What is a Breakaway Connector?

Leave a CommentWhat is a Breakaway Connector?

A breakaway connector is an electrical safety component used on cables to disconnect corded equipment from moving components or rotating machinery. If rotating or moving machinery starts to move while a sensor or cable is tangled within it, the breakaway connector will disconnect immediately so the corded equipment isn’t dragged into the moving equipment.

Breakaway connectors are commonly used with data collection equipment that connects to rotating machines, but they can be used for virtually any application where cords and corded equipment are in potential danger from high tensile loads. These components are also sometimes called weak links or weak fuses.

Best Materials for Breakaway Connectors

Breakaway connectors can be constructed from a wide variety of plastic and metal alloy options. Plastics provide lightweight, cost-effective components that resist corrosion damage. However, manufacturing plastic breakaway connectors does require an upfront investment to design and develop tooling for the molding process. Plastic may also wear down faster than other material options.

Metals such as aluminum offer another viable and popular choice. This material is more resistant to wear and damage than plastic, while remaining lightweight and easy to work with. However, aluminum is more vulnerable to corrosion damage than plastic. Heavier metal options include brass and stainless steel. While these options are more resistant to corrosion and physical damage, the additional weight can interfere with the effectiveness of the component.

It’s possible to enhance corrosion resistance and other properties on plastic or metal breakaway connectors through plating.

The Importance of Plating and Color for Breakaway Connectors

By plating metal or plastic breakaway connectors with thin layers of other materials, manufacturers can imbue connectors with the positive characteristics of multiple materials. Chroming aluminum components, for example, allows for the use of lightweight metal while protecting it from corrosion.

Breakaway connectors also come in different colors, and those colors communicate important attributes of the connector. For example, mating pairs of components can have the same color so technicians can easily pair the parts together. Colors may also designate brand, orientation, and material characteristics for the connectors, depending on the application.

Breakaway Connectors From Amphenol NEXUS Technologies

At Amphenol NEXUS Technologies, we specialize in manufacturing and supplying 7- and 10-pin breakaway connectors with a durable, waterproof design. We provide a wide range of standard and miniature breakaway components, plugs, and jacks for an array of applications, including:

- C4I systems

- Military aircraft

- Commercial aircraft

- Military ground vehicles

- Soldier systems

- Missiles and ordnance

- Commercial/industrial equipment

Contact us today to see how our breakaway cables and components can improve safety in your operation.

What is a Push Button Switch?

Leave a CommentWhat is a Push Button Switch?

A push button switch is a simple mechanism that initiates power to a machine, device, or appliance. The body is typically metal or plastic, featuring a durable and ergonomic design. With switches available that provide latching or momentary action, there are push button switches for virtually any relevant application. This blog will explain how push button switches work and discuss typical applications for various push button switch types.

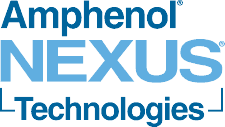

How Does a Push Button Switch Work?

Push button switches can serve many purposes, but each type operates on a similar principle. When an operator applies pressure to the push button actuator, an internal spring depresses. Contacts attached to the spring connect with the electrical contacts on the switch’s lower end to open or close the electrical circuit. Depending on the switch, releasing the button or pressing it again will retract the spring and return the circuit to its original state.

The initial state of the push button circuit can be open or closed, depending on the application. The type of switch will also depend on the application.

Push Button Switch Types

Push button switches come in two types: momentary switches or push-pull switches.

- Momentary. The momentary push button switch has a single pole and is initially in an off state. When the operator presses the push button switch, it changes to on. There are also double-pole momentary switches that provide an additional state of functionality.

- Push-pull. Push-pull switches are typically in an off state until an operator presses the button and engages the actuator. The machine or device will remain on until an operator pulls the actuator to its initial position.

Selecting a Push Button Switch for Military Applications

Military push button switches undergo rigorous testing and quality control. They must meet high reliability and performance requirements, in addition to ergonomic specifications. Relevant military specifications for push buttons include MIL-S-8805/3 and MS25089. Military push buttons require numerous capabilities, such as:

- Electromagnetic immunity

- Extreme temperature operation

- Resistance to salt spray

- IP67 or IP68 waterproofing

- Shock and vibration resistance

- Matte black chrome finish

Push Button Switches From Amphenol NEXUS Technologies

Amphenol Nexus Technologies can produce durable and tactile momentary switches and push-pull switches. Our experts have extensive experience designing and manufacturing rugged switches used in numerous commercial, industrial, marine, and military settings, such as:

- Industrial machinery

- Soldier systems

- Command systems

- Ruggedized communications systems

- Naval systems

- Ground vehicles

- Avionics

- Commercial and military aircraft

Our custom switches allow us to meet your exact specifications, and our military push button switches comply with MIL-S-8805/3 and MS25089. We also manufacture connectors that make it simple to implement our push button switches.

To see how we can help with your next project, please contact us today.

What is the Difference Between Microphone Plugs & Jacks?

Leave a CommentWhat is the Difference Between Microphone Plugs & Jacks?

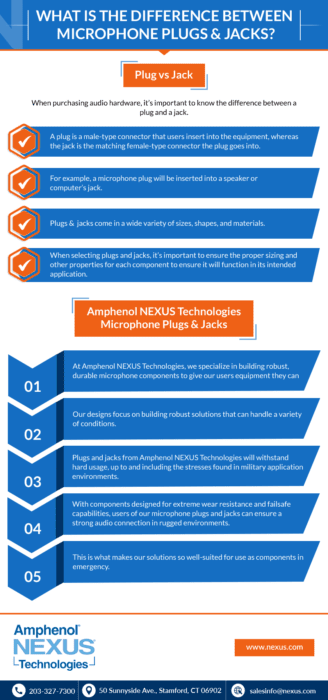

Even with the continued rise of wireless technology, many high-quality headsets, microphones, and other audio equipment still rely on wired connections to boost sound quality and functionality. How these devices plug into computers and larger pieces of equipment matters, as does the material used to make the contact points.

When purchasing audio hardware, it’s important to know the difference between a plug and a jack. A plug is a male-type connector that users insert into the equipment, whereas the jack is the matching female-type connector the plug goes into. For example, a microphone plug will be inserted into a speaker or computer’s jack. Plugs and jacks come in a wide variety of sizes, shapes, and materials. When selecting plugs and jacks, it’s important to ensure the proper sizing and other properties for each component to ensure it will function in its intended application.

Amphenol NEXUS Technologies Microphone Plugs & Jacks

At Amphenol NEXUS Technologies, we specialize in building robust, durable microphone components to give our users equipment they can rely on. Our designs focus on building robust solutions that can handle a variety of conditions.

For example, we incorporate nylon into our plug designs. Nylon is a synthetic material that has broad use cases ranging from clothing to electronics. This material is corrosion-resistant, insulative, wear-resistant, lightweight, and easy to customize. These properties make nylon an optimal choice for protective housings used on our ruggedized plugs and jacks used in even the harshest applications.

Plugs and jacks from Amphenol NEXUS Technologies will withstand hard usage, up to and including the stresses found in military application environments. Aside from the protective nylon housings, we’ve ruggedized our components by choosing strong materials and designing the jack-plug contacts to withstand hectic conditions. Beryllium is very ductile, making it an excellent choice for forming detailed geometries with specific dimensions. Adding nickel plating protects the beryllium by reducing the potential for diffusion and degradation. It also adds a bright, appealing finish.

With components designed for extreme wear resistance and failsafe capabilities, users of our microphone plugs and jacks can ensure a strong audio connection in rugged environments. This is what makes our solutions so well-suited for use as components in emergency commercial, municipal, and military communication systems.

Amphenol NEXUS Technologies for Rugged Applications

Since 1961, our team at Amphenol NEXUS has been designing and manufacturing audio plugs and jacks for a broad range of rugged application environments. We specialize in microphone and OEM headsets that are built to last and provide a trustworthy audio connection.

Contact us today to learn more about our capabilities or product line.