| Part Number | NX-A10WAM- P09XMM0-0000 (High Density) | NX-A10WAM- P12XMM0-0000 (High Density) | NX-A10WAM- P16XBC0-0000 (High Density) | NX-A11WAM- P27XBC0-0000 (High Density) | NX-K10WAM- P09WMM0-0000 (High Density) | NX-K10WAM- P12WMM0-0000 (High Density) | NX-K10WAM- P16WBC0-0000 (High Density) | NX-K11WAM- P27WBC0-0000 (High Density) | NX-GK0WAM- P09WMM0-000L (High Density) | NX-GK0WAM- P12WMM0-000L (High Density) | NX-GK0WAM- P16WBC0-000L (High Density) | NX-GK1WAM- P27WBC0-000L (High Density) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

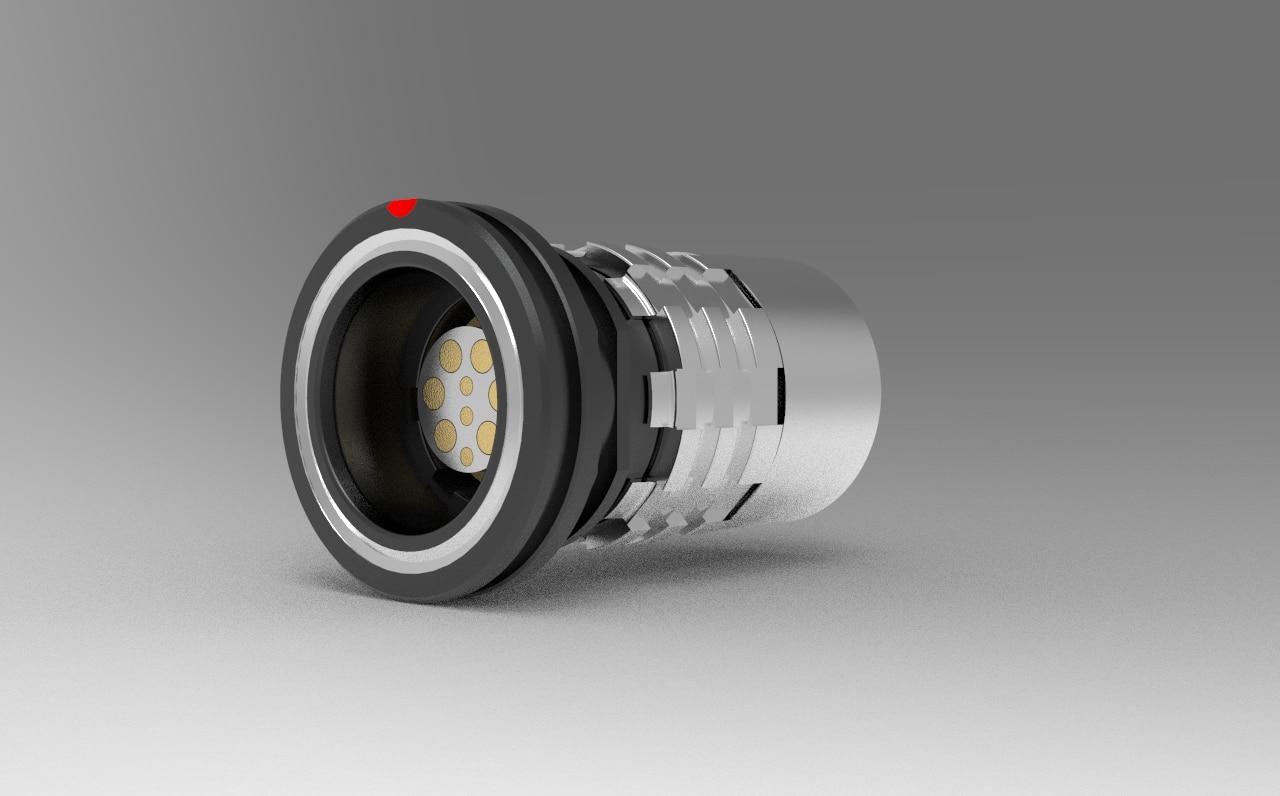

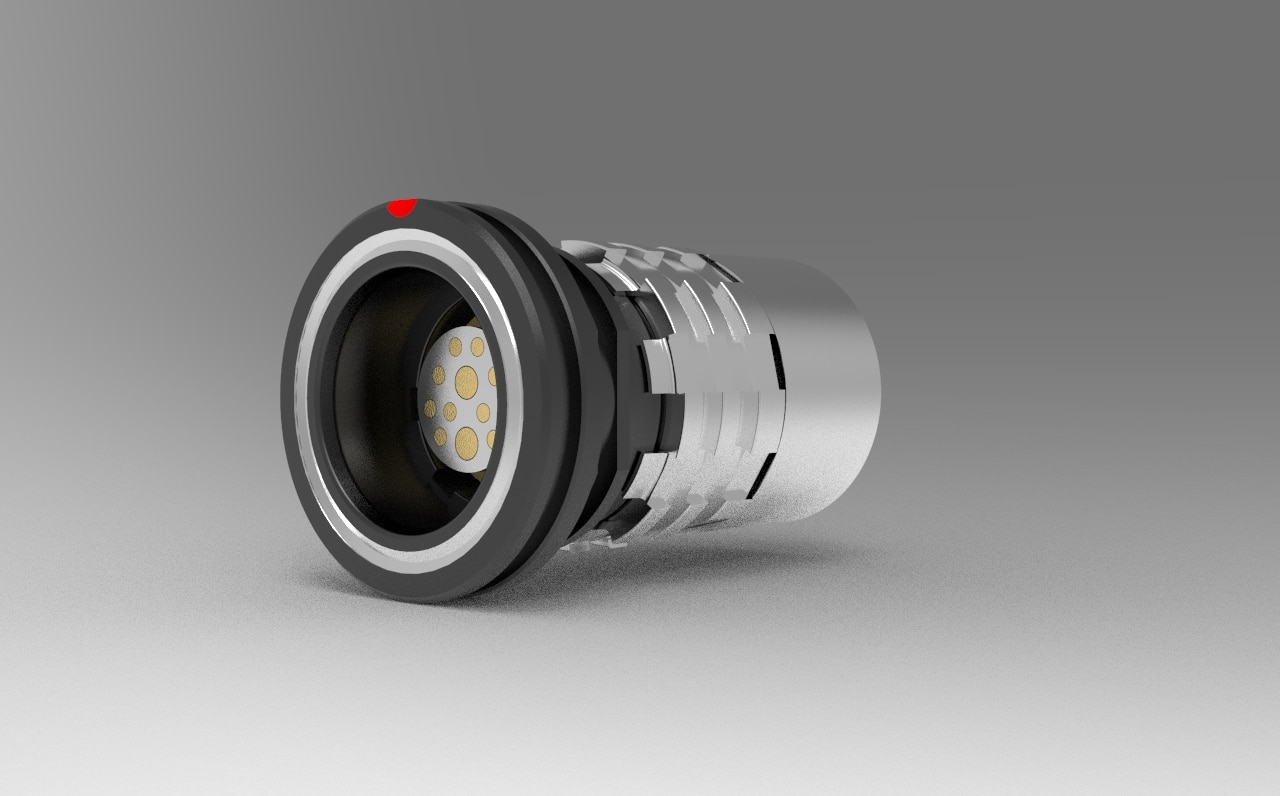

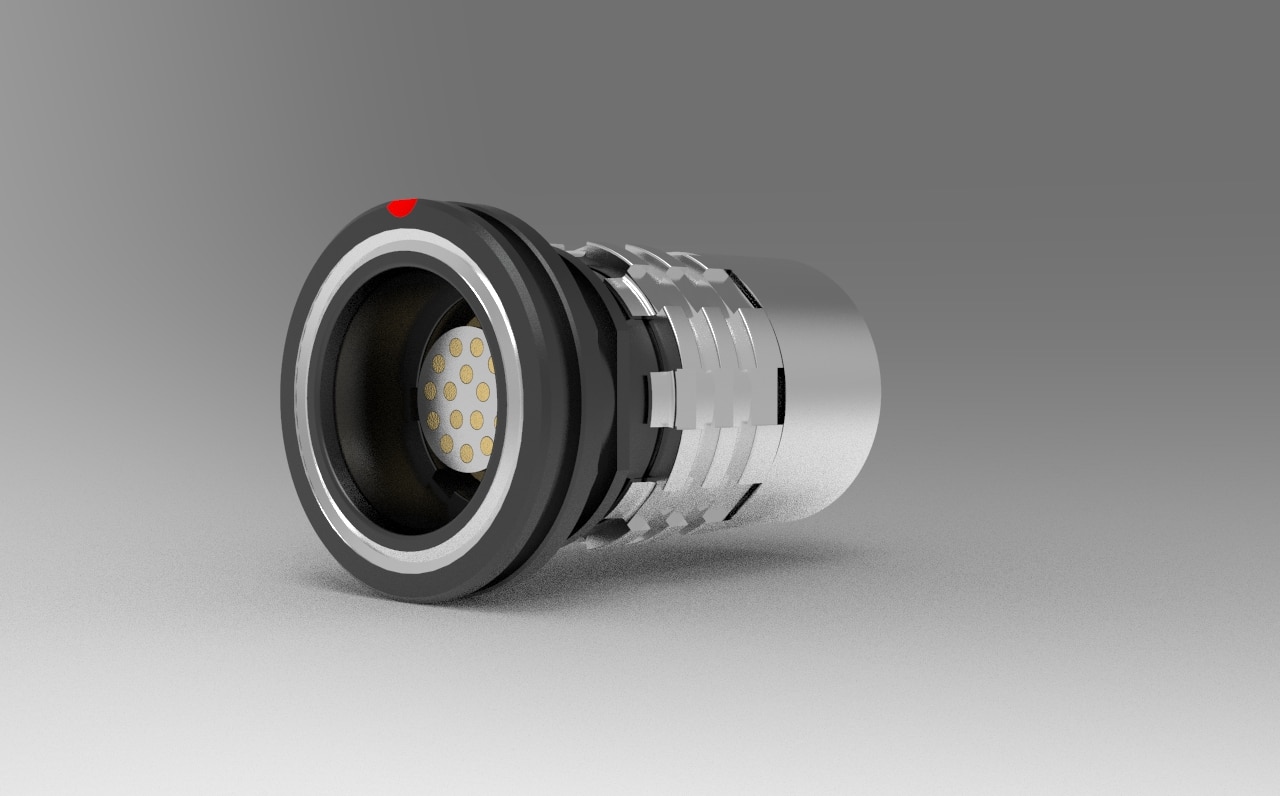

| Images |  |  |  |  |  |  |  |  |  |  |  |  |

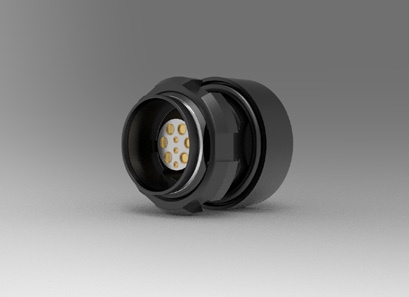

| Type of Connector | Straight Plug | Straight Plug | Straight Plug | Straight Plug | In-Line Receptacle | In-Line Receptacle | In-Line Receptacle | In-Line Receptacle | Rear Panel Mount Receptacle | Rear Panel Mount Receptacle | Rear Panel Mount Receptacle | Rear Panel Mount Receptacle |

| Size | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 |

| Number of Contacts | 9 | 12 | 16 | 27 | 9 | 12 | 16 | 27 | 9 | 12 | 16 | 27 |

| Keying | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown |

| Contact Type | Pins | Pins | Pins | Pins | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets |

| Contact Diameter | 3x 0.3 mm; 6x 0.7 mm | 10x 0.3 mm. 2x 0.7 mm | 0.3 mm | 0.3 mm | 3x 0.3 mm; 6x 0.7 mm | 10x 0.3 mm. 2x 0.7 mm | 0.3 mm | 0.3 mm | 3x 0.3 mm; 6x 0.7 mm | 10x 0.3 mm. 2x 0.7 mm | 0.3 mm | 0.3 mm |

| Insulator Material | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK |

| Wire Cross Section | 22 AWG; 28 AWG | 22 AWG; 28AWG | 28AWG | 28AWG | 22 AWG; 28 AWG | 23 AWG; 28 AWG | 28AWG | 28AWG | 22 AWG; 28 AWG | 23 AWG; 28 AWG | 28 AWG | 29 AWG |

| Termination Type | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder |

| Data Transmission | USB 2.0 (480 Mbit/s) + Power | USB 3.2 Gen 1×1 (5 Gbit/s) | USB 2.0 (480 Mbit/s) + Power | HDMI 1.3 (8.13 Gbit/s) | USB 2.0 (480 Mbit/s) + Power | USB 3.2 Gen 1×1 (5 Gbit/s) | USB 2.0 (480 Mbit/s) + Power | HDMI 1.3 (8.13 Gbit/s) | USB 2.0 (480 Mbit/s) + Power | USB 3.2 Gen 1×1 (5 Gbit/s) | USB 2.0 (480 Mbit/s) + Power | HDMI 1.3 (8.13 Gbit/s) |

| Degree of Protection | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K |

| Operating Temperature | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C |

| Mating Cycles | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 |

| Shell Finish | Cu-alloy with ruthenium finish | Cu-alloy with ruthenium finish | Cu-alloy with ruthenium finish | Cu-alloy with ruthenium finish | Cu-alloy with ruthenium finish | Cu-alloy with ruthenium finish | Cu-alloy with ruthenium finish | Cu-alloy with ruthenium finish | Cu-alloy with ruthenium finish | Cu-alloy with ruthenium finish | Cu-alloy with ruthenium finish | Cu-alloy with ruthenium finish |

| Contact Finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish |

| Current Rate (Amps) | 1A, 5A | 1A, 5A | 1A | 1A | 1A, 5A | 1A, 5A | 1A | 1A | 1A, 5A | 1A, 5A | 1A | 1A |

| Voltage | 250VAC | 250VAC | 250VAC | 250VAC | 250VAC | 250VAC | 250VAC | 250VAC | 250VAC | 250VAC | 250VAC | 250VAC |

| Alternative Part # | A10WAM-P09XMM0-0000 | A10WAM-P12XMM0-0000 | A10WAM-P16XBC0-0000 | A11WAM-P27XBC0-0000 | K10WAM-P09WMM0-0000 | K10WAM-P12WMM0-0000 | K10WAM-P16WBC0-0000 | K11WAM-P27WBC0-0000 | GK0WAM-P09WMM0-000L | GK0WAM-P12WMM0-000L | GK0WAM-P16WBC0-000L | GK1WAM-P27WBC0-000L |

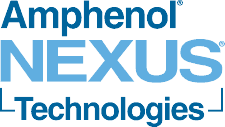

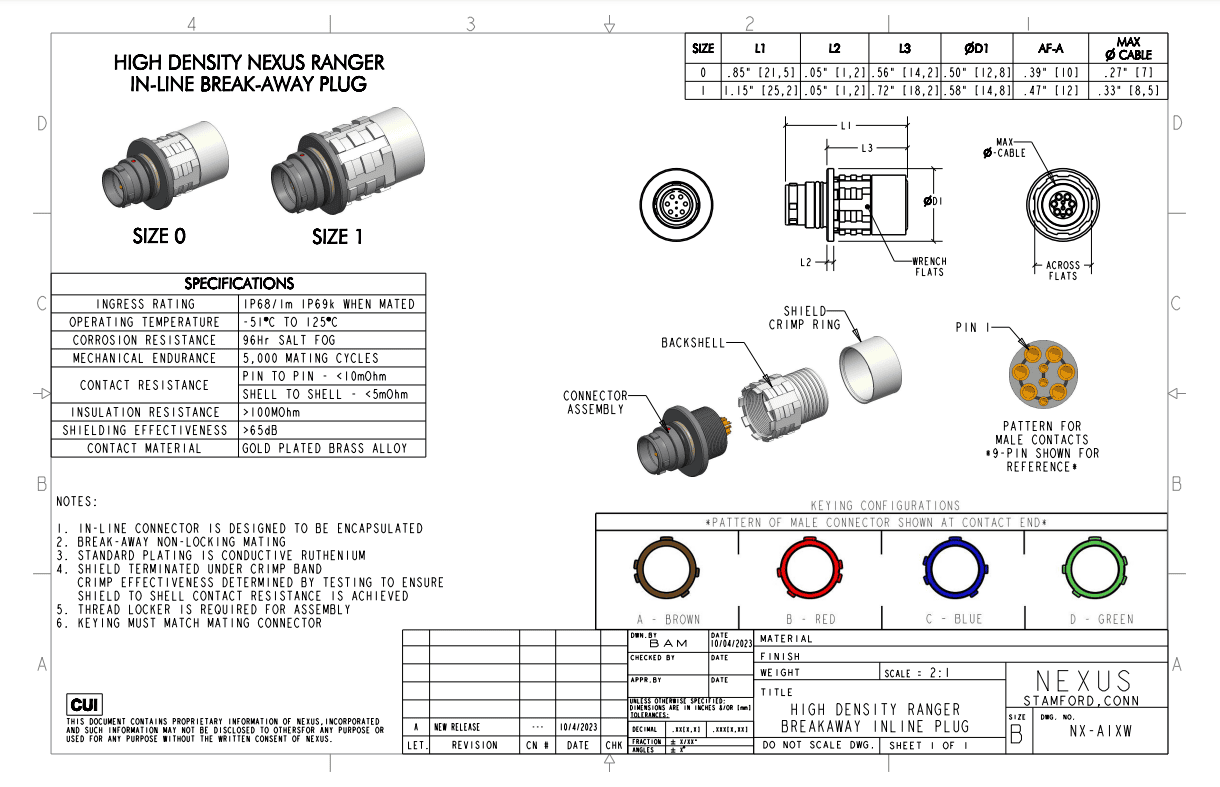

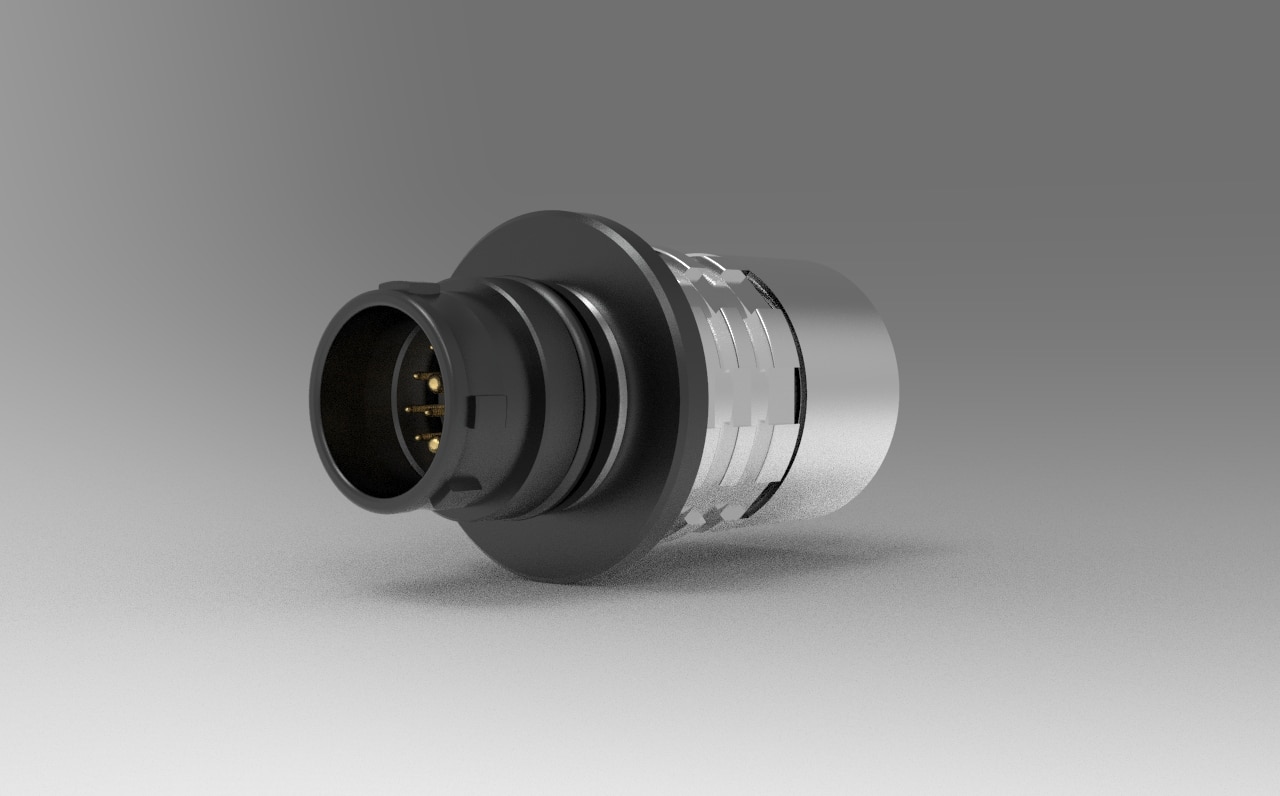

The High-Density Ranger series by Amphenol NEXUS Technologies is developed for applications that demand reliability, compact design, and consistent electrical performance under pressure. These connectors meet the needs of defense, aerospace, and industrial sectors that face rugged environmental and mechanical conditions.

Built to support high-density contact layouts without compromising durability, the High-Density Ranger series offers reliable signal integrity in situations where space is limited and performance expectations are high. These connectors are frequently integrated into systems that require frequent mating cycles, resistance to moisture, and tolerance to high vibration.

What Sets the High-Density Ranger Apart

The High-Density Ranger connector line features contact layouts that maximize performance within a compact footprint. Available configurations include up to 27 contacts, offering 0.3 mm and 0.7 mm contact diameters. This layout flexibility allows engineers to meet demanding space and electrical requirements with a single connector solution.

Each connector features a durable shell design with conductive ruthenium plating, providing corrosion resistance under extreme environmental conditions. Internally, the use of gold-plated brass alloy contacts supports reliable conductivity over thousands of cycles. The insulator material is made from PEEK (polyether ether ketone), which is known for its excellent thermal stability and resistance to mechanical stress.

Technical Capabilities

The High-Density Ranger connector supports modern data transmission protocols, including:

- USB 2.0 at 480 Mbit/s

- USB 3.2 Gen 1×1 at 5 Gbit/s

- HDMI 1.3 at 8.13 Gbit/s

These features allow it to support video, communication, and control signals in a wide range of applications. The connector is rated for up to 5,000 mating cycles, making it suitable for systems that require repeated connection and disconnection. With an IP68/IP69K sealing rating when mated, it provides protection against dust and water ingress, including high-pressure washdowns.

Operating temperature range spans from -51°C to +125°C, maintaining functionality across extreme climates and mission-critical field conditions.

The High-Density Ranger is available in three mechanical formats:

- Straight Plug

- In-Line Receptacle

- Rear Panel Mount Receptacle

This variety allows engineers to integrate the connector into various enclosure types and wiring layouts without compromise. Each design maintains the same rugged construction, high contact density, and precision fit.

Ranger Distribution List Wave 3: High Density

| Part Number | NX-A10WDM-P09XMM0-0000 | NX-A10WCM-P09XMM0-0000 | NX-A10WDM-P09XMM0-0000 | NX-A10WBM-P12XMM0-0000 | NX-A10WCM-P12XMM0-0000 | NX-K10WDM-P09WMM0-0000 | NX-K10WBM-P12WMM0-0000 | NX-K10WCM-P12WMM0-0000 | NX-GK0WCM-P09UM00-000L | NX-GK0WDM-P09UM00-000L | NX-GK0WCM-P12UM00-000L | NX-GK0WBM-P12UM00-000L | NX-C10WAM-P09XMM0-0000 | NX-C10WDM-P09XMM0-0000 | NX-GC0WAM-P09UM00-000L | NX-GC0WDM-P09UM00-000L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Image |  |  |  |  |  |  |  |  |  |  |  |  |  |  |  |  |

| Type of Connector | 9 pin HD Plug | 9 pin HD Plug | 9 pin HD Plug | 12 pin HD Plug | 12 pin HD Plug | 9 pin HD Receptacle | 12 pin HD Receptacle | 12 pin HD Receptacle | 9 pin Rear Panel Mount Receptacle | 9 pin Rear Panel Mount Receptacle | 12 pin Rear Panel Mount Receptacle | 12 pin Rear Panel Mount Receptacle | 9 pin HD Screw Lock Plug | 9 pin HD Screw Lock Plug | 9 pin HD Screw Lock Receptacle | 9 pin HD Screw Lock Receptacle |

| Size | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| Number of Contacts | 9 | 9 | 9 | 12 | 12 | 9 | 12 | 12 | 9 | 9 | 12 | 12 | 9 | 9 | 9 | 9 |

| Keying | Green | Blue | Green | Red | Blue | Green | Red | Blue | Blue | Green | Blue | Red | Brown | Green | Brown | Green |

| Contact Type | Pins | Pins | Pins | Pins | Pins | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets | Pins | Pins | Sockets | Sockets |

| Contact Diameter | 3x 0.3 mm; 6×0.7 mm | 3x 0.3 mm; 6x 0.7 mm | 3x 0.3 mm; 6x 0.7 mm | 10x 0.3 mm; 2x 0.7 mm | 10x 0.3 mm; 2x 0.7 mm | 3x 0.3 mm; 6x 0.7 mm | 10x 0.3 mm; 2x 0.7 mm | 10x 0.3 mm; 2x 0.7 mm | 3x 0.3 mm; 6x 0.7 mm | 3x 0.3 mm; 6x 0.7 mm | 10x 0.3 mm; 2x 0.7 mm | 10x 0.3 mm; 2x 0.7 mm | 3x 0.3 mm; 6×0.7 mm | 3x 0.3 mm; 6×0.7 mm | 3x 0.3 mm; 6x 0.7 mm | 3x 0.3 mm; 6x 0.7 mm |

| Cable Diameter | 3.2 – 7.0 mm | NA | NA | NA | NA | 3.2 – 7.0 mm | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| Insulator Material | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK |

| Wire Cross Section | 22AWG; 28AWG | 22AWG; 28AWG | 22AWG; 28AWG | 22AWG; 28AWG | 22AWG; 28AWG | 22AWG; 28AWG | 23AWG; 28AWG | 23AWG; 28AWG | NA | NA | NA | NA | 22AWG; 28AWG | 22AWG; 28AWG | NA | NA |

| Termination Type | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | PCB | PCB | PCB | PCB | Solder | Solder | PCB | PCB |

| Termination Diameter | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | 0.3 mm; 0.8 mm | NA |

| Data Transmission | USB 2.0 (480 Mbit/s) + Power | USB 2.0 (480 Mbit/s) + Power | USB 2.0 (480 Mbit/s) + Power | USB 3.2 Gen 1×1 (5 Gbit/s) | USB 3.2 Gen 1×1 (5 Gbit/s) | USB 2.0 (480 Mbit/s) + Power | USB 3.2 Gen 1×1 (5 Gbit/s) | USB 3.2 Gen 1×1 (5 Gbit/s) | USB 2.0 (480 Mbit/s) + Power | USB 2.0 (480 Mbit/s) + Power | USB 3.2 Gen 1×1 (5 Gbit/s) | USB 3.2 Gen 1×1 (5 Gbit/s) | USB 2.0 (480 Mbit/)s + Power | USB 2.0 (480 Mbit/)s + Power | USB 2.0 (480 Mbit/)s + Power | USB 2.0 (D+, D-) |

| Degree of Protection | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP68K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP68K8 / IP6K9K | IP68K8 / IP6K9K |

| Operating Temperature | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C |

| Mating Cycles | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 |

| Shell Finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish |

| Contact Finish | Cu-alloy with gold finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with Ruthenium finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish |

| Current Rate (Amps) | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A | 1A, 5A |

| Voltage | 0.75 kVDC | 250VAC | 250VAC | 250VAC | 250VAC | 0.75 kVDC | 250VAC | 250VAC | 0.75 kVDC | 0.75 kVDC | 0.75 kVDC | 0.75 kVDC | 0.75 kVDC | 0.75 kVDC | 0.75 kVDC | 0.75 kVDC |

| Alternative Part # | A10WDM- P09XMM0- 0000 | A10WCM- P09XMM0- 0000 | A10WDM- P09XMM0- 0000 | A10WBM- P12XMM0- 0000 | A10WCM- P12XMM0- 0000 | K10WDM- P09WMM0- 0000 | K10WBM- P12WMM0- 0000 | K10WCM- P12WMM0- 0000 | GK0WCM- P09WMM0- 000L | GK0WDM- P09WMM0- 000L | GK0WCM- P12WMM0- 000L | GK0WCM- P12WMM0- 000L | C10WDM- P09XMM0- 0000 | C10WDM- P09XMM0- 0000 | GC0WAM- P09UM00- 000L | GC0WDM- P09UM00- 000L |

Built for Demanding Applications

The High-Density Ranger serves multiple industries where size, performance, and resilience matter:

- Military and Defense: Used in communication systems, power distribution, and field equipment.

- Aerospace: Installed in avionics, control systems, and instrumentation.

- Industrial: Applied in robotics, machinery interfaces, and automation equipment.

- Telecommunications: Supports high-speed data in remote and mobile systems.

These sectors rely on components that perform reliably under physical stress and environmental exposure. The High-Density Ranger provides the needed performance while minimizing bulk and installation time.

Why Choose the High-Density Ranger

Selecting the High-Density Ranger means gaining a connector that delivers high contact counts, small form factor, and high-speed data support in a ruggedized design. It allows product teams to meet demanding project specifications without compromising on connection quality or service life.

Amphenol NEXUS Technologies continues to deliver connection systems that align with field-tested performance expectations. The High-Density Ranger represents a continuation of that focus, built with materials and designs that match long-term performance requirements.

Request a Quote or Contact Our Team

To learn more about how the High-Density Ranger can support your project requirements or to speak with an engineer about specifications and availability, please feel free to contact us today.