| Part Number | NX-A10YAR- P09XCD0-0000 | NX-A11YAR- P08XFG0-0000 | NX-A11YAR- P14XCD0-0000 | NX-A11YAR- P16XCD0-0000 | NX-K10YAR- P09WCD0-000 | NX-K11YAR- P08WFG0-0000 | NX-K11YAR- P14WCD0-0000 | NX-K11YAR- P16WCD0-0000 | NX-G80YAR- P09WCD0-000L | NX-G81YAR- P08WFG0-000L | NX-G81YAR- P14WCD0-000L | NX-G81YAR- P16WCD0-000L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

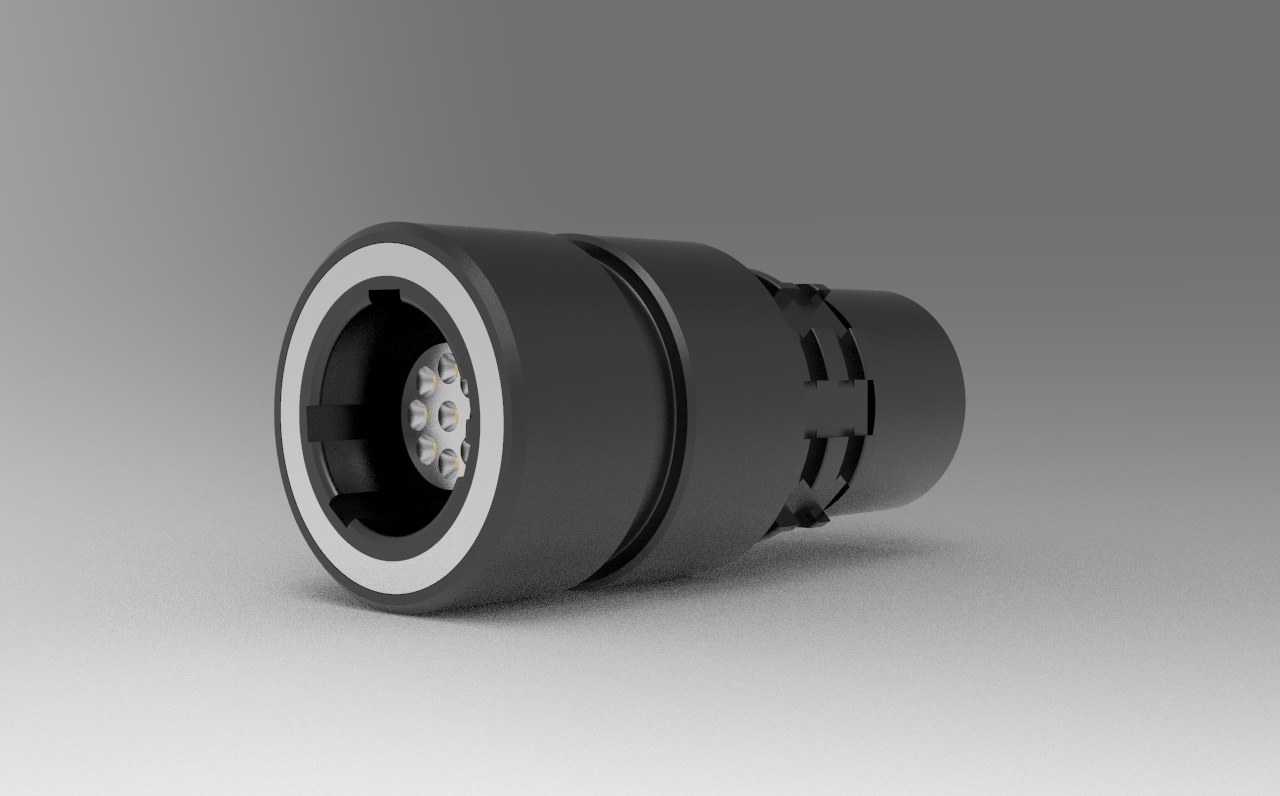

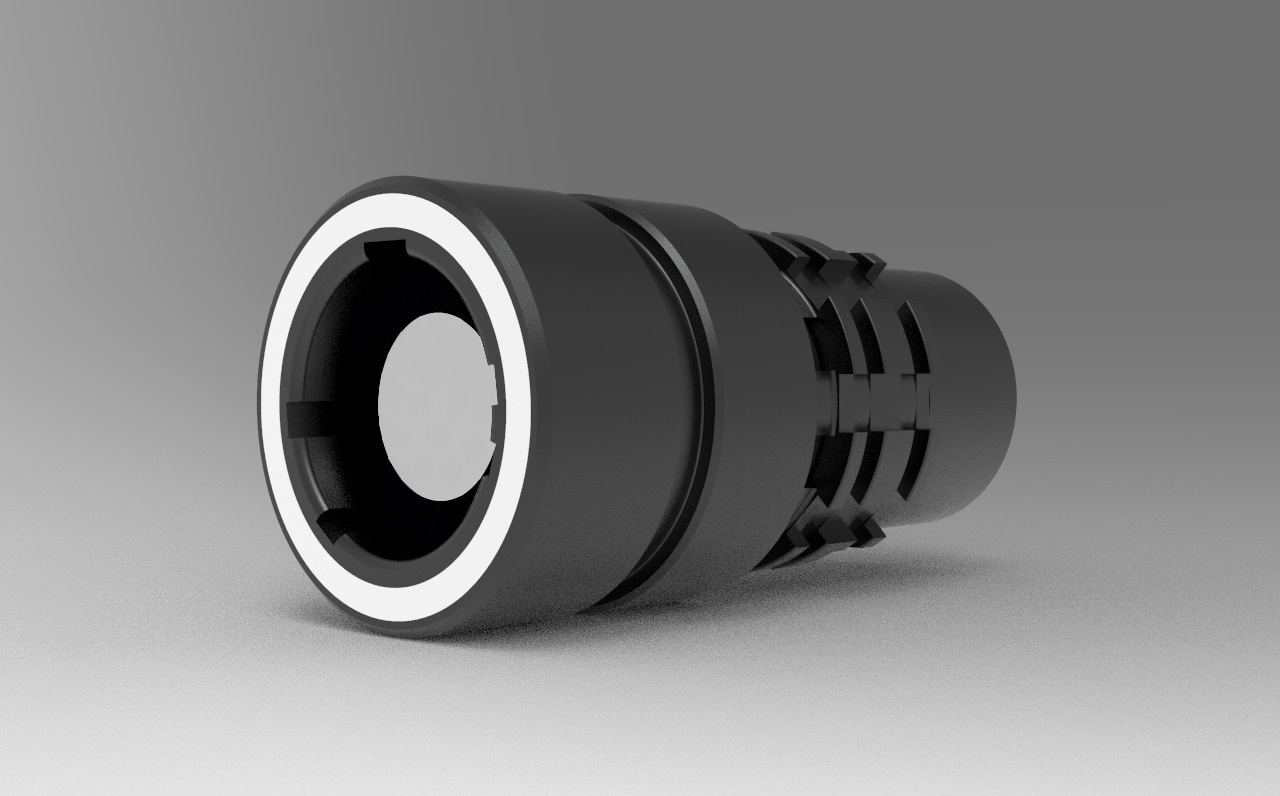

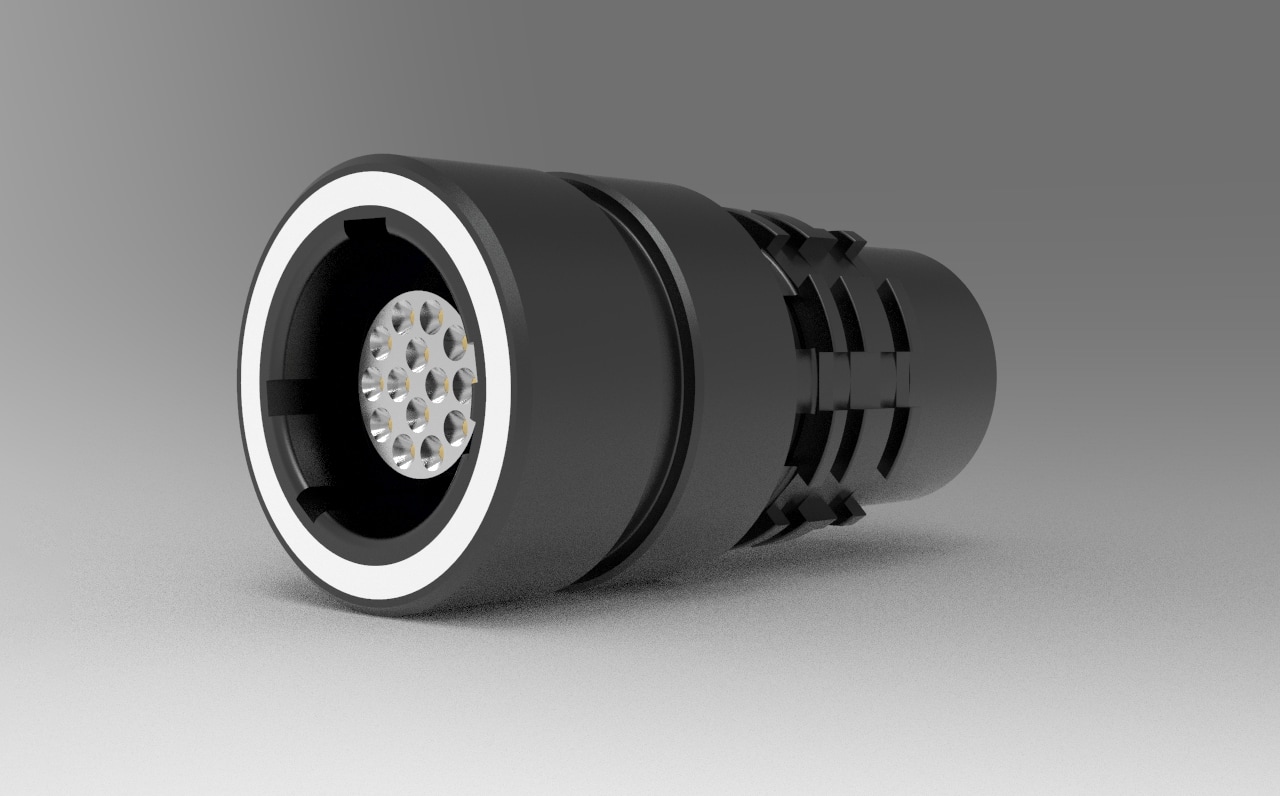

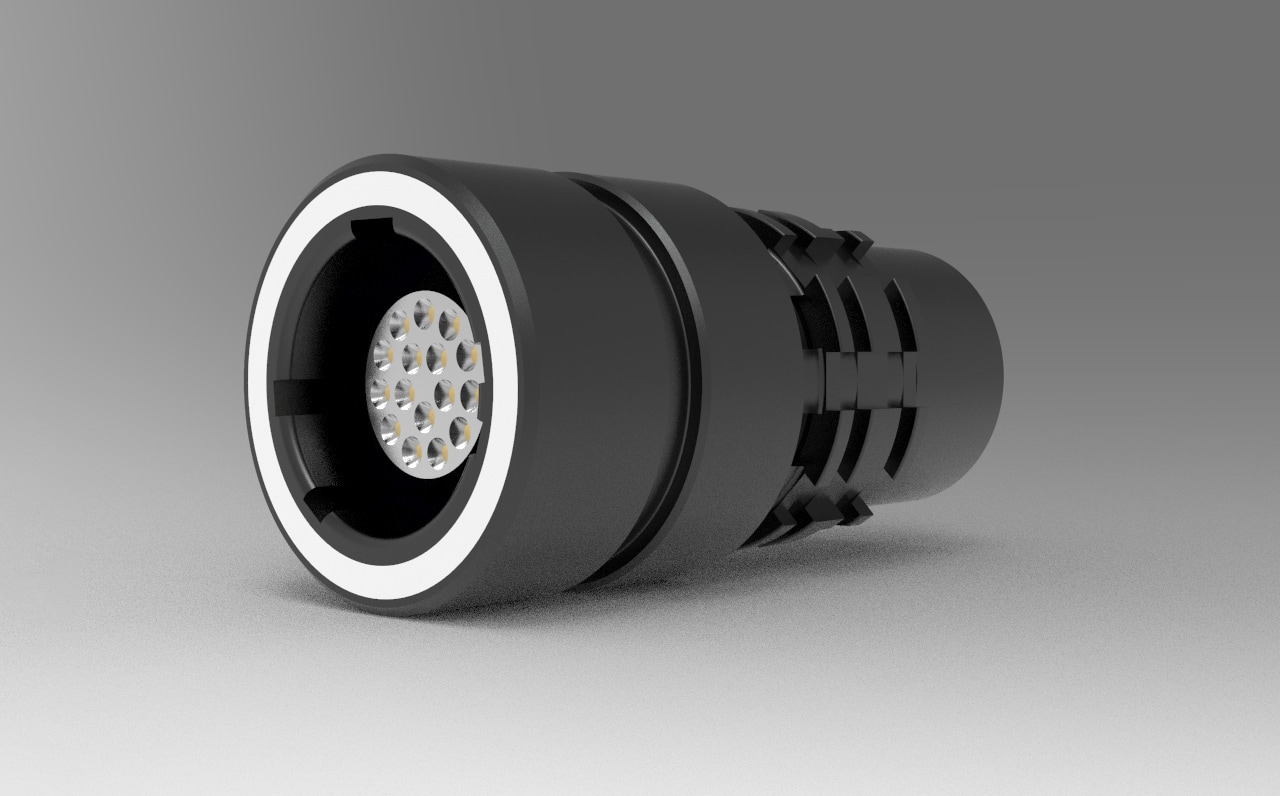

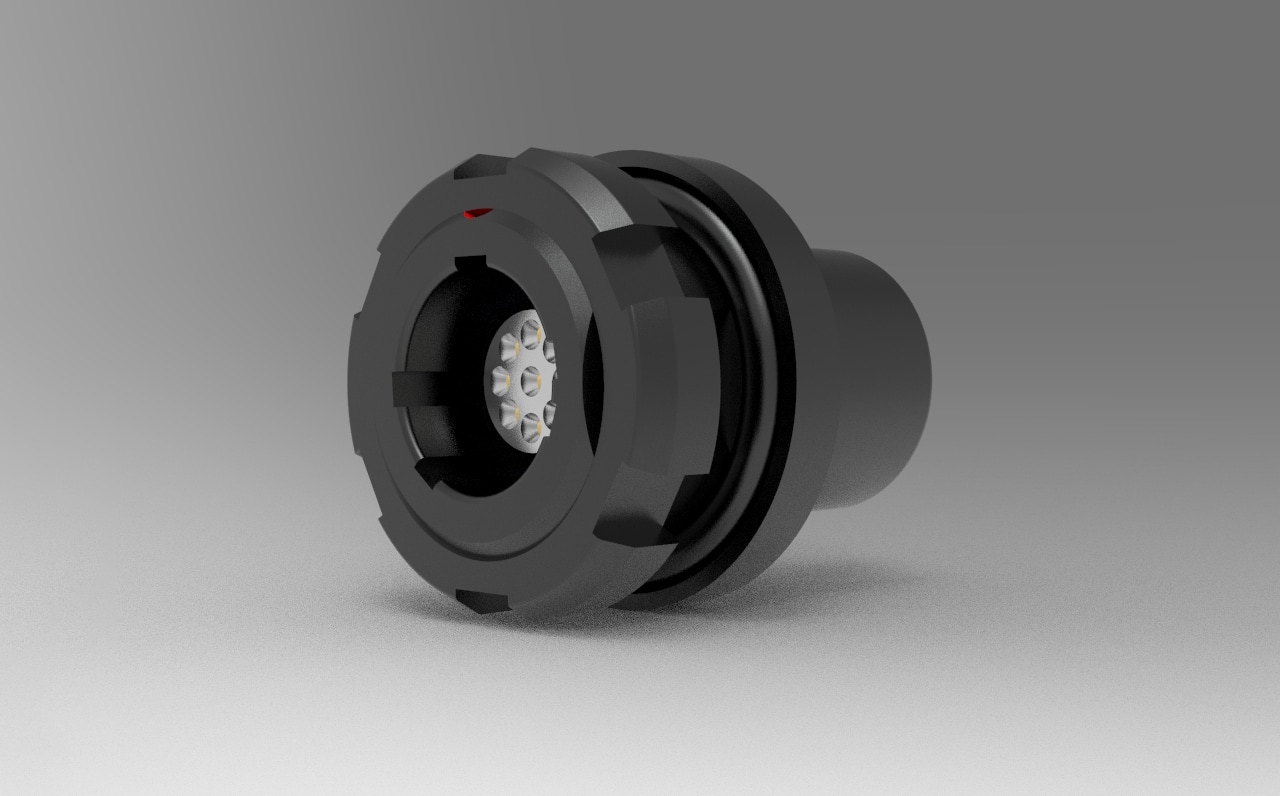

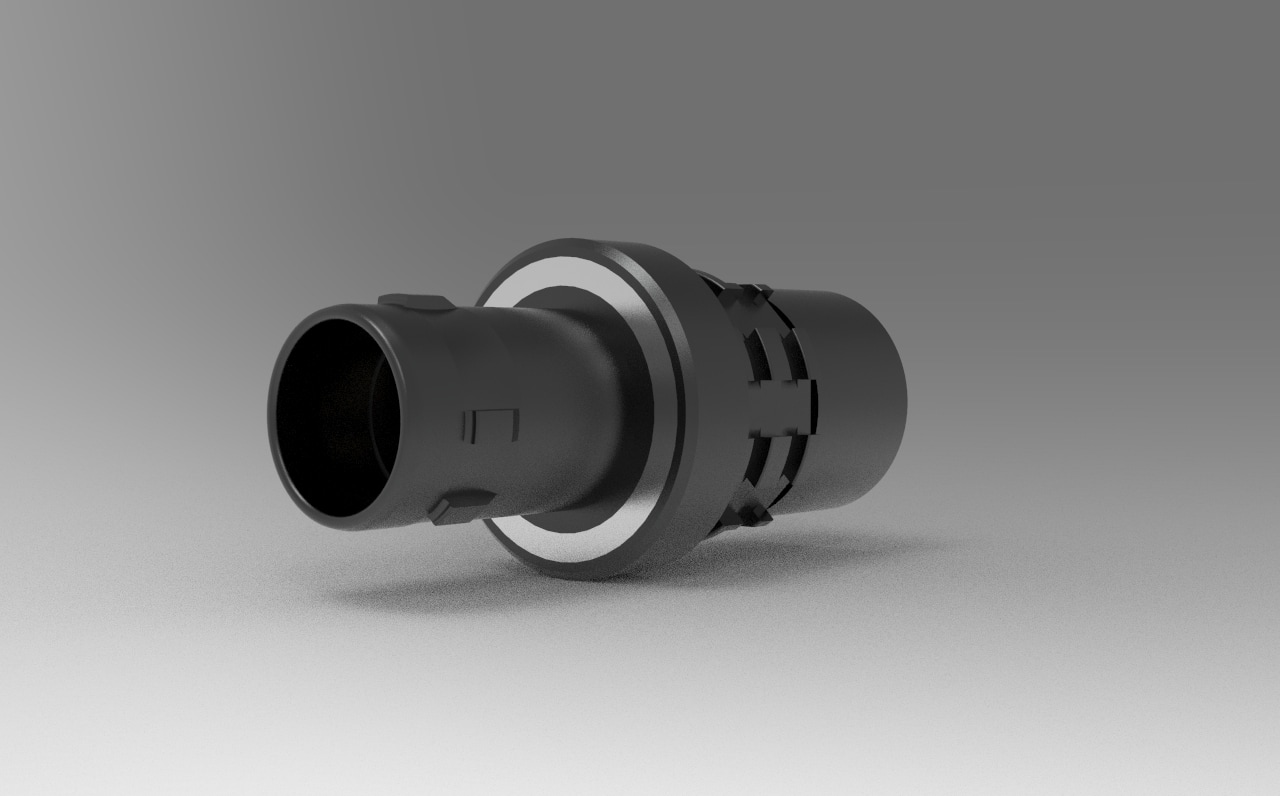

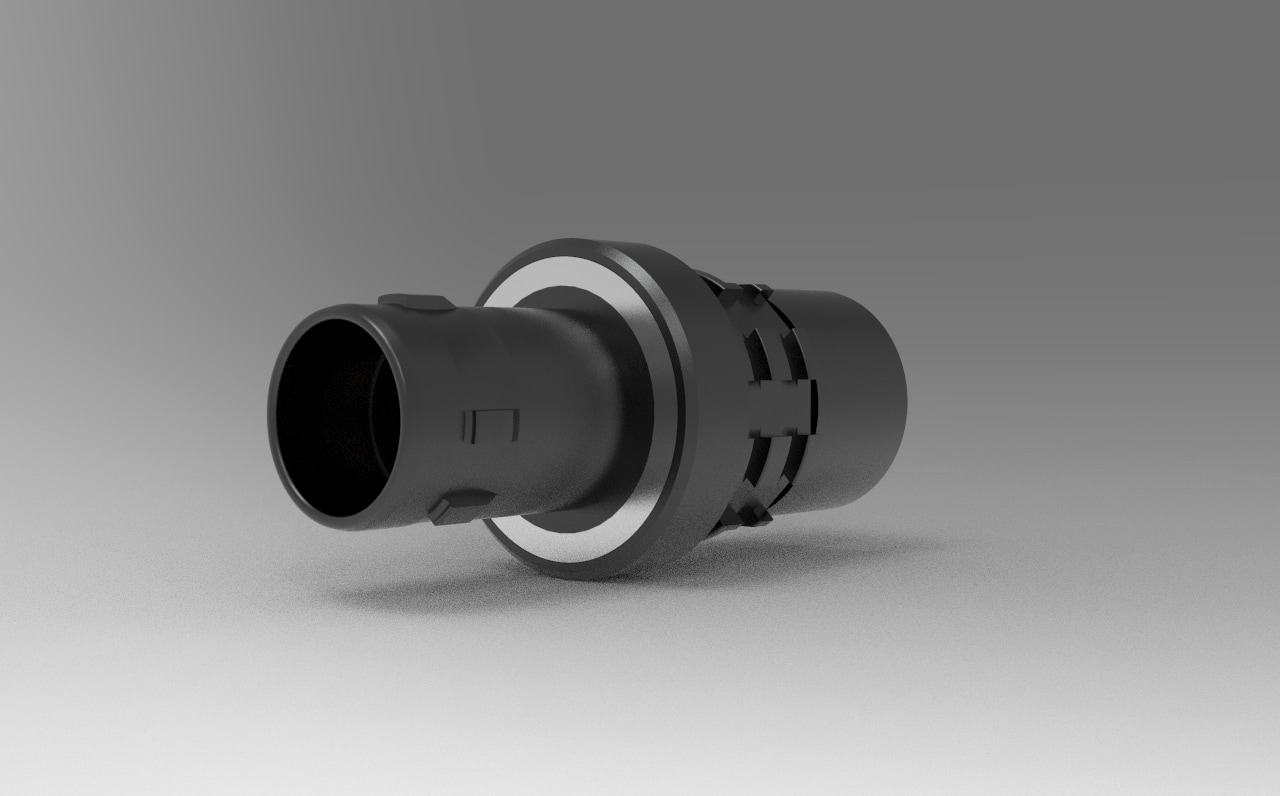

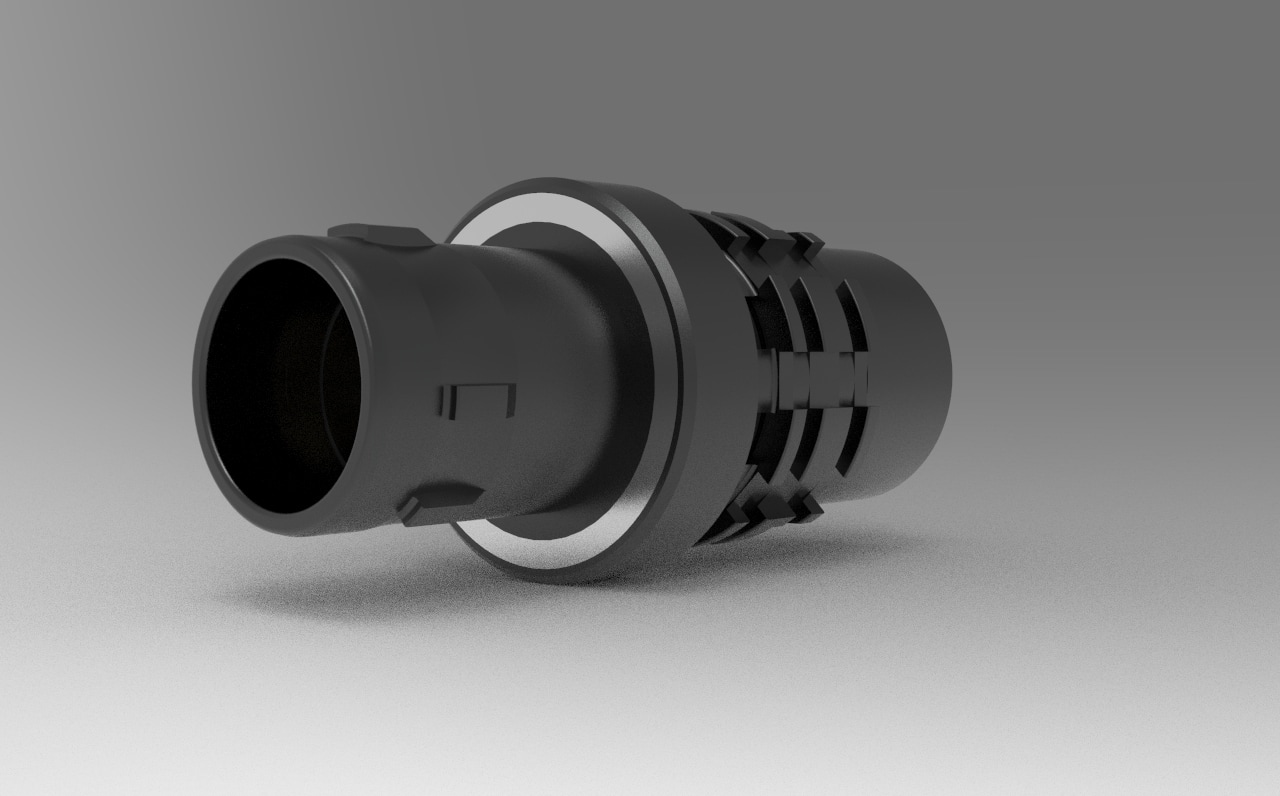

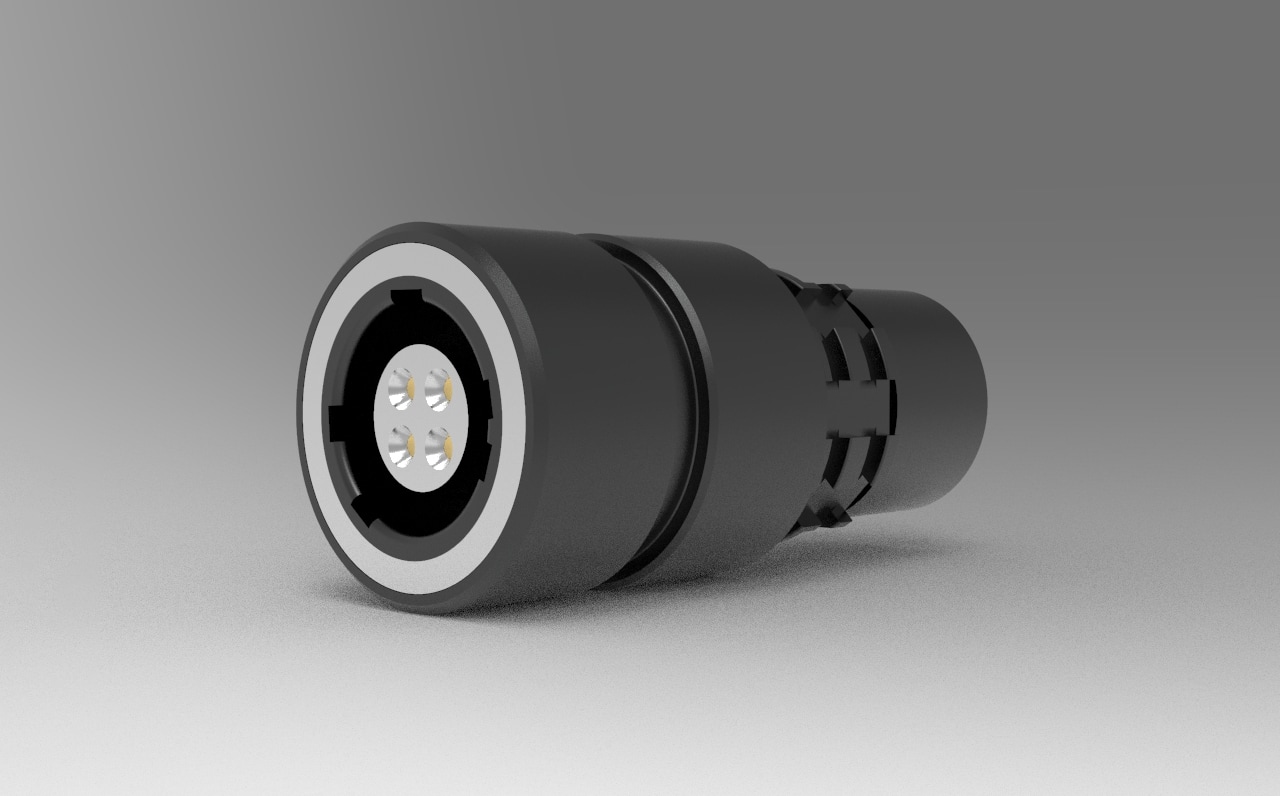

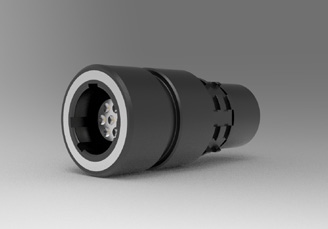

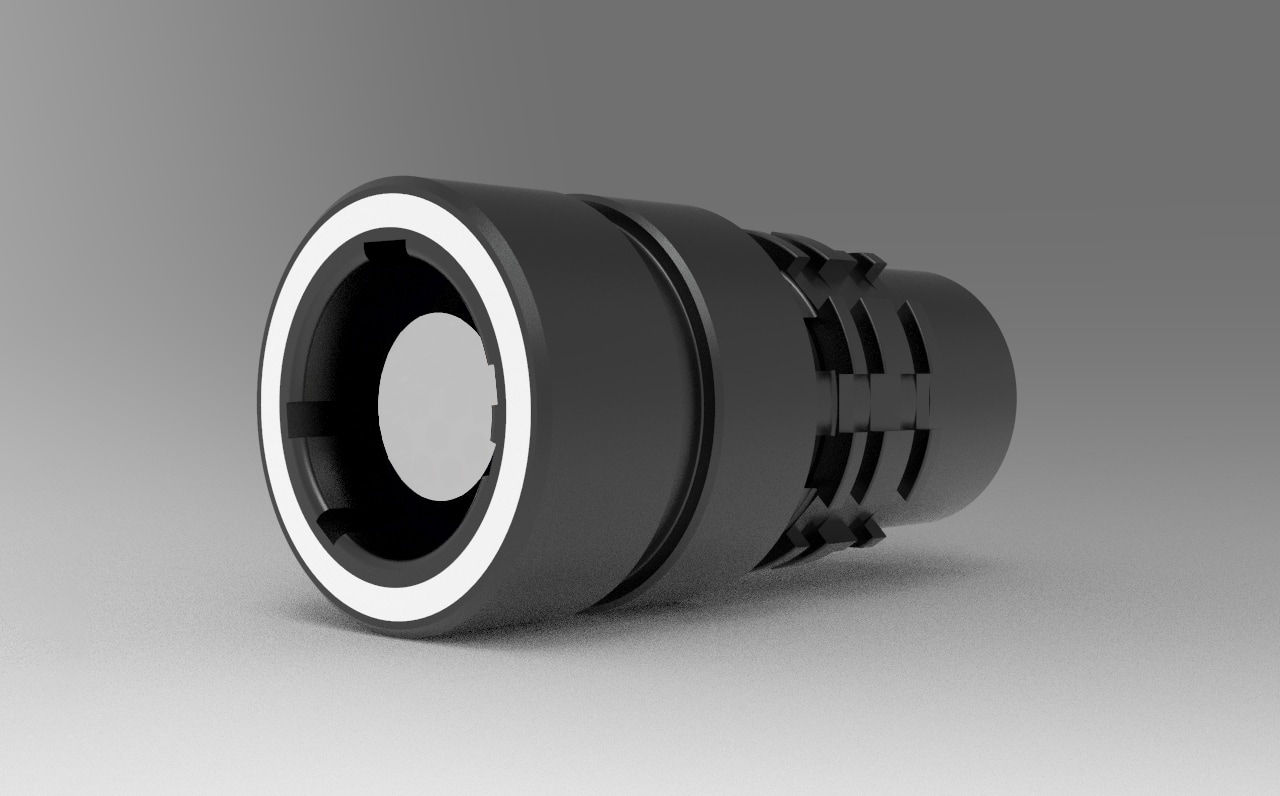

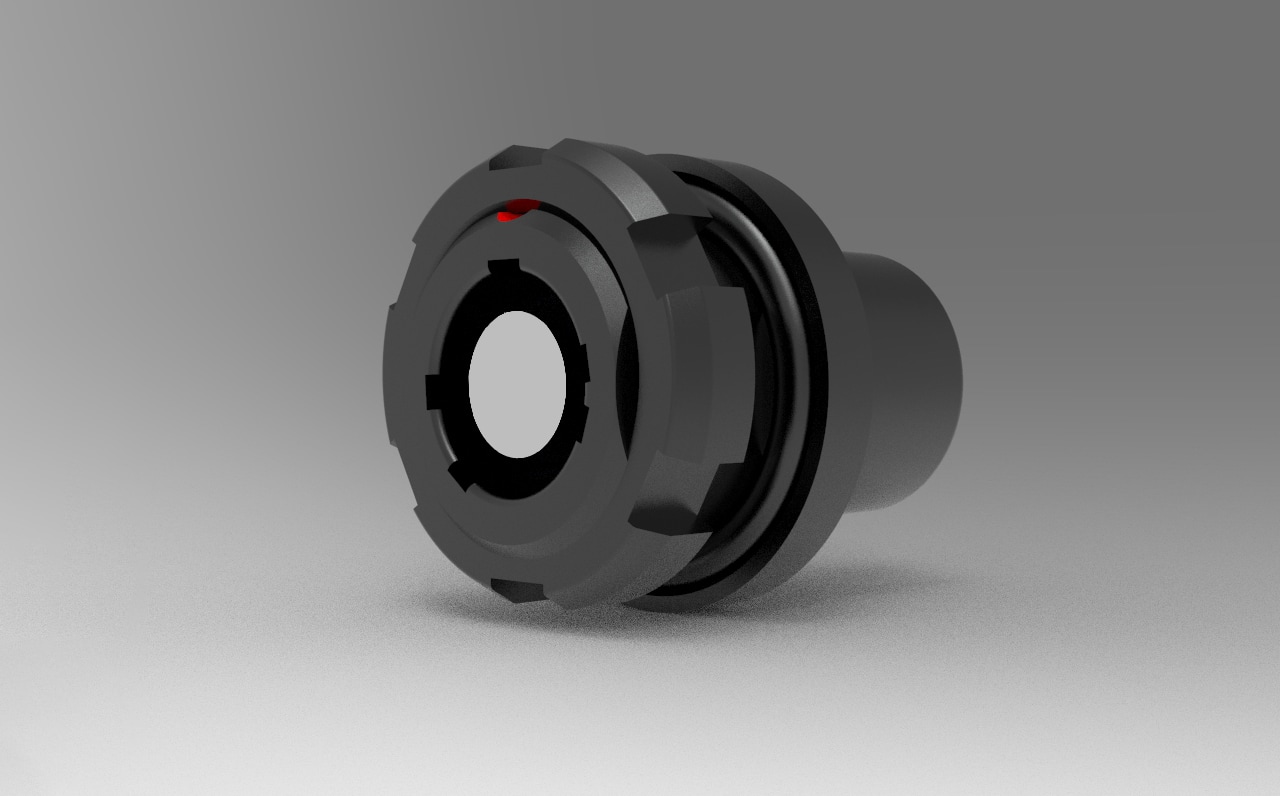

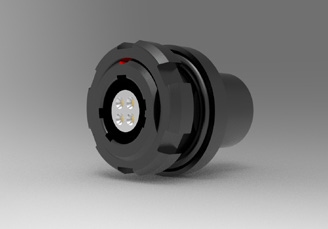

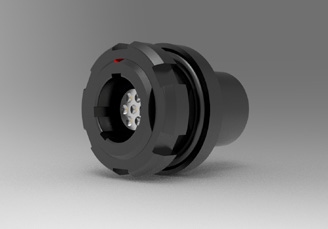

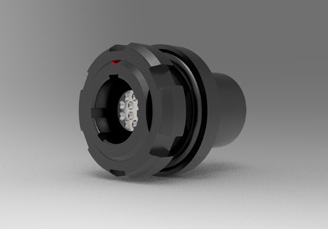

| Images |  |  |  |  |  |  |  |  |  |  |  |  |

| Type of Connector | Straight Plug | Straight Plug | Straight Plug | Straight Plug | In-Line Receptacle | In-Line Receptacle | In-Line Receptacle | In-Line Receptacle | Rear Panel Mount Receptacle | Rear Panel Mount Receptacle | Rear Panel Mount Receptacle | Rear Panel Mount Receptacle |

| Size | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 |

| Number of Contacts | 9 | 8 | 14 | 16 | 9 | 8 | 14 | 16 | 9 | 8 | 14 | 16 |

| Keying | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown |

| Contact Type | Pins | Pins | Pins | Pins | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets |

| Contact Diameter | 0.5 mm | 0.7 mm | 0.5 mm | 0.5 mm | 0.5 mm | 0.7 mm | 0.5 mm | 0.5 mm | 0.5 mm | 0.7 mm | 0.5 mm | 0.5 mm |

| Cable Diameter | 3-5.5 mm | 3.2 – 6.5 mm | 3.2 – 6.5 mm | 3.2 – 6.5 mm | 3-5.5 mm | 6.5 mm | 3.2 – 6.5 mm | 3.2 – 6.5 mm | 3-5.5 mm | 3.2 – 6.5 mm | 3.2 – 6.5 mm | 3.2 – 6.5 mm |

| Insulator Material | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK |

| Wire Cross Section | 26AWG | 22AWG | 26AWG | 26AWG | 26AWG | 22AWG | 26AWG | 26AWG | 26AWG | 22AWG | 26AWG | 26AWG |

| Termination Type | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder |

| Termination Diameter | 0.65 mm | 0.85 mm | 0.65 mm | 0.65 mm | 0.65 mm | 0.85 mm | 0.65 mm | 0.65 mm | 0.65 mm | 0.85 mm | 0.65 mm | 0.65 mm |

| Data Transmission | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| Degree of Protection | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K |

| Operating Temperature | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C |

| Mating Cycles | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 |

| Shell Finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish |

| Contact Finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish |

| Current Rate (Amps) | 5A | 7A | 5A | 5A | 5A | 7A | 5A | 5A | 5A | 7A | 5A | 5A |

| Voltage | 200V | 333V | 300V | 200V | 200V | 333V | 300V | 200V | 200V | 333V | 300V | 200V |

| Alternative Part # | A10YAR-P09CD0-0000 | A11YAR-P08FG0-0000 | A11YAR-P14CD0-0000 | A11YAR-P16CD0-0000 | K10YAR-P09CD0-0000 | K11YAR-P08FG0-0000 | K11YAR-P14CD0-0000 | K11YAR-P16CD0-0000 | G80YAR-P09CD0-000L | G81YAR-P08WFG0-000L | G81YAR-P14WCD0-000L | G81YAR-P16WCD0-000L |

The Standard Ranger is a dependable connector solution developed by Amphenol NEXUS Technologies. Known for its mechanical strength and environmental resistance, this series is used across industries that demand consistent performance in harsh conditions. The Standard Ranger sits within the broader Ranger product family and is valued for its straightforward interface and durability over extended use.

Highlights of the Standard Ranger

This connector series includes features engineered for long-term performance. The Standard Ranger supports up to 5,000 mating cycles, making it ideal for frequent connect/disconnect scenarios. Its aluminum housing with a ruthenium finish offers physical protection without adding unnecessary weight. Rated to function between -51°C and +125°C, the series is built to operate in a wide range of environmental settings.

Electrical and Mechanical Performance

The Standard Ranger supports both 5A and 10A current ratings, depending on the configuration and voltage requirements. Contact options include 0.5 mm, 0.7 mm, and 0.9 mm diameters, with gold plating over Cu-alloy for corrosion resistance and signal reliability. These electrical characteristics allow engineers to match system requirements without compromise.

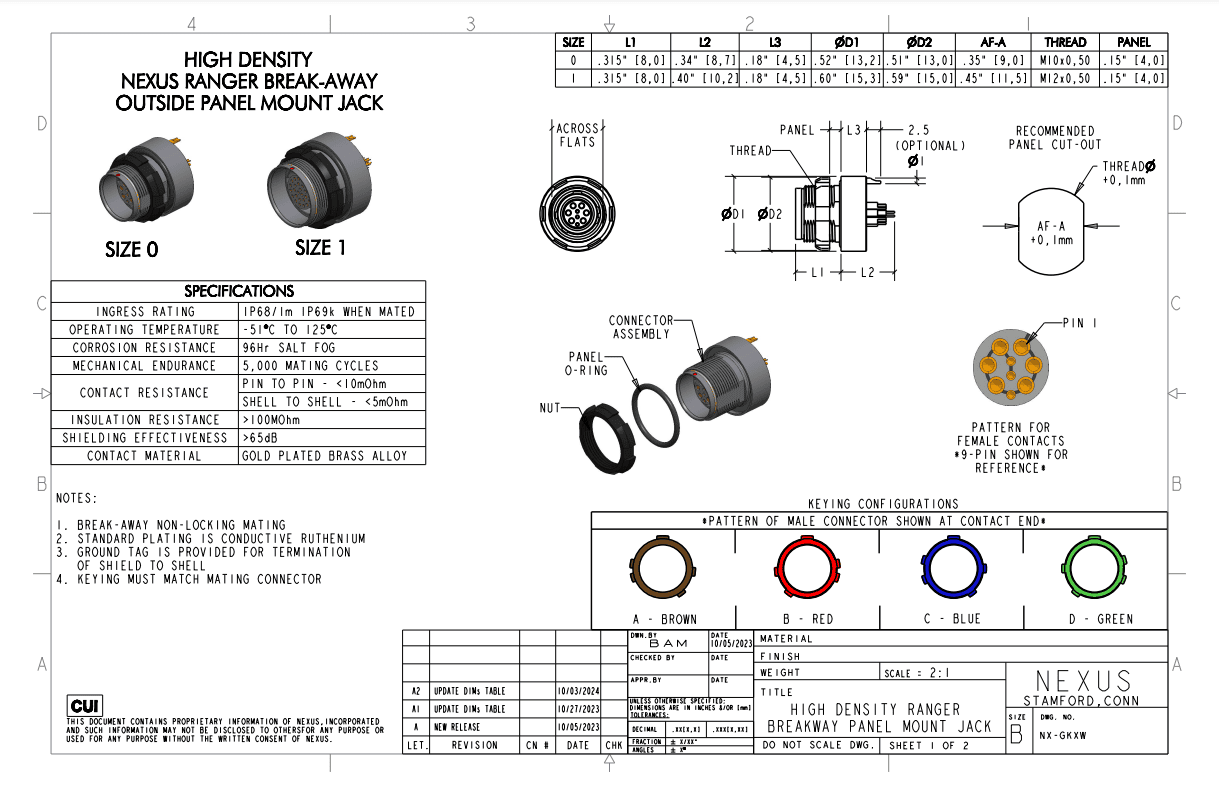

High Density Product Types:

We have various types of Standard products available; check out our Standard product list. These are the following standard products:

- 3 point contact: NX-A10YAR-P03XJG0-0000

- 4 point contact: NX-A10YAR-P04XFG0-0000

- 7 point contact: NX-A10YAR-P07XCD0-0000

- 9 point contact: NX-A10YAR-P09XCD0-0000

- 10 point contact: NX-A10YAR-P10XCD0-0000

- 5 point contact: NX-A11YAR-P05XJG0-0000

- 8 point contact: NX-A11YAR-P08XFG0-0000

- 14 point contact: NX-A11YAR-P14XCD0-0000

- 16 point contact: NX-A11YAR-P16XCD0-0000

- 3 point contact: NX-K10YAR-P03WJG0-0000

- 4 point contact: NX-K10YAR-P04WFG0-0000

- 7 point contact: NX-K10YAR-P07WCD0-0000

- 9 point contact: NX-K10YAR-P09WCD0-0000

- 10 point contact: NX-K10YAR-P10WCD0-0000

- 5 point contact: NX-K11YAR-P05WJG0-0000

- 8 point contact: NX-K11YAR-P08WFG0-0000

- 14 point contact: NX-K11YAR-P14WCD0-0000

- 16 point contact: NX-K11YAR-P16WCD0-0000

- 3 point contact: NX-G80YAR-P03WJG0-000L

- 4 point contact: NX-G80YAR-P04WFG0-000L

- 7 point contact: NX-G80YAR-P07WCD0-000L

- 9 point contact: NX-G80YAR-P09WCD0-000L

- 10 point contact: NX-G80YAR-P10WCD0-000L

- 5 point contact: NX-G81YAR-P05WJG0-000L

- 8 point contact: NX-G81YAR-P08WFG0-000L

- 14 point contact: NX-G81YAR-P14WCD0-000L

- 16 point contact: NX-G81YAR-P16WCD0-000L

Standard Versions Continuted

| Part Number | NX-A10YAR- P03X JG0-0000 | NX-A10YAR- P04X FG0-0000 | NX-A10YAR- P07X CD0-0000 | NX-A10YAR- P10X CD0-0000 | NX-A11YAR- P05X JG0-0000 | NX-K10YAR- P03W JG0-0000 | NX-K10YAR- P04W FG0-0000 | NX-K10YAR- P07W CD0-0000 | NX-K10YAR- P10W CD0-0000 | NX-K11YAR- P05W JG0-0000 | NX-G80YAR- P03W JG0-000L | NX-G80YAR- P04W FG0-000L | NX-G80YAR- P07W CD0-000L | NX-G80YAR- P10W CD0-000L | NX-G81YAR- P05W JG0-000L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Images |  |  |  |  |  |  |  |  |  |  |  |  |  |  |  |

| Type of Connector | Straight Plug | Straight Plug | Straight Plug | Straight Plug | Straight Plug | In-Line Receptacle | In-Line Receptacle | In-Line Receptacle | In-Line Receptacle | In-Line Receptacle | Rear Panel Mount Receptacle | Rear Panel Mount Receptacle | Rear Panel Mount Receptacle | Rear Panel Mount Receptacle | Rear Panel Mount Receptacle |

| Size | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 |

| Number of Contacts | 3 | 4 | 7 | 10 | 5 | 3 | 4 | 7 | 10 | 5 | 3 | 4 | 7 | 10 | 5 |

| Keying | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown | Brown |

| Contact Type | Pins | Pins | Pins | Pins | Pins | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets | Sockets |

| Contact Diameter | 0.9 mm | 0.7 mm | 0.5 mm | 0.5 mm | 0.9 mm | 0.9 mm | 0.7 mm | 0.5 mm | 0.5 mm | 0.9 mm | 0.9 mm | 0.7 mm | 0.5 mm | 0.5 mm | 0.9 mm |

| Cable Diameter | 3 – 5.5 mm | 4 – 5.5 mm | 3-5.5 mm | 3-5.5 mm | 3.2 – 6.5 mm | 3 – 5.5 mm | 3 – 5.5 mm | 4 – 5.5 mm | 3-5.5 mm | 6.5 mm | 3 – 5.5 mm | 3-5.5 mm | 3-5.5 mm | 3-5.5 mm | 3.2 – 6.5 mm |

| Insulator Material | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | PEEK |

| Wire Cross Section | 22AWG | 22AWG | 26AWG | 26AWG | 22AWG | 22AWG | 22AWG | 26AWG | 26AWG | 22AWG | 22AWG | 22AWG | 26AWG | 26AWG | 22AWG |

| Termination Type | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder | Solder |

| Termination Diameter | 0.85 mm | 0.85 mm | 0.65 mm | 0.65 mm | 0.85 mm | 0.85 mm | 0.85 mm | 0.65 mm | 0.65 mm | 0.85 mm | 0.85 mm | 0.85 mm | 0.65 mm | 0.65 mm | 0.85 mm |

| Data Transmission | NA | USB 2.0(480 Mbit/s) | NA | NA | NA | NA | NA | NA | NA | NA | NA | USB 2.0 (480 Mbit/s) | NA | NA | NA |

| Degree of Protection | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP6K9K | IP6K8 / IP-6K9K | IP6K8 / IP-6K9K | IP6K8 / IP-6K9K |

| Operating Temperature | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C | -51°C – 125°C |

| Mating Cycles | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 |

| Shell Finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish | Aluminum with ruthenium finish |

| Contact Finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish | Cu-alloy with gold finish |

| Current Rate (Amps) | 10A | 7A | 5A | 5A | 10A | 10A | 7A | 5A | 5A | 10A | 10A | 7A | 5A | 5A | 10A |

| Voltage | 400V | 300V | 300V | 200V | 450V | 400V | 300V | 300V | 200V | 450V | 400V | 300V | 300V | 200V | 450V |

| Alternative Part # | A10YAR-P03X JG0-0000 | A10YAR-P04X FG0-0000 | A10YAR-P07X CD0-0000 | A10YAR-P10X CD0-0000 | A11YAR-P05X JG0-0000 | K10YAR-P03X JG0-0000 | K10YAR-P04X FG0-0000 | K10YAR-P07W CD0-0000 | K10YAR-P10 CD0-0000 | K11YAR-P05 JG0-0000 | G80YAR-P03 JG0-000L | G80YAR-P04 WFG0-000L | G80YAR-P07 WCD0-000L | G80YAR-P10 CD0-000L | G81YAR-P05 JG0-000L |

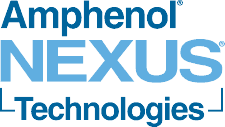

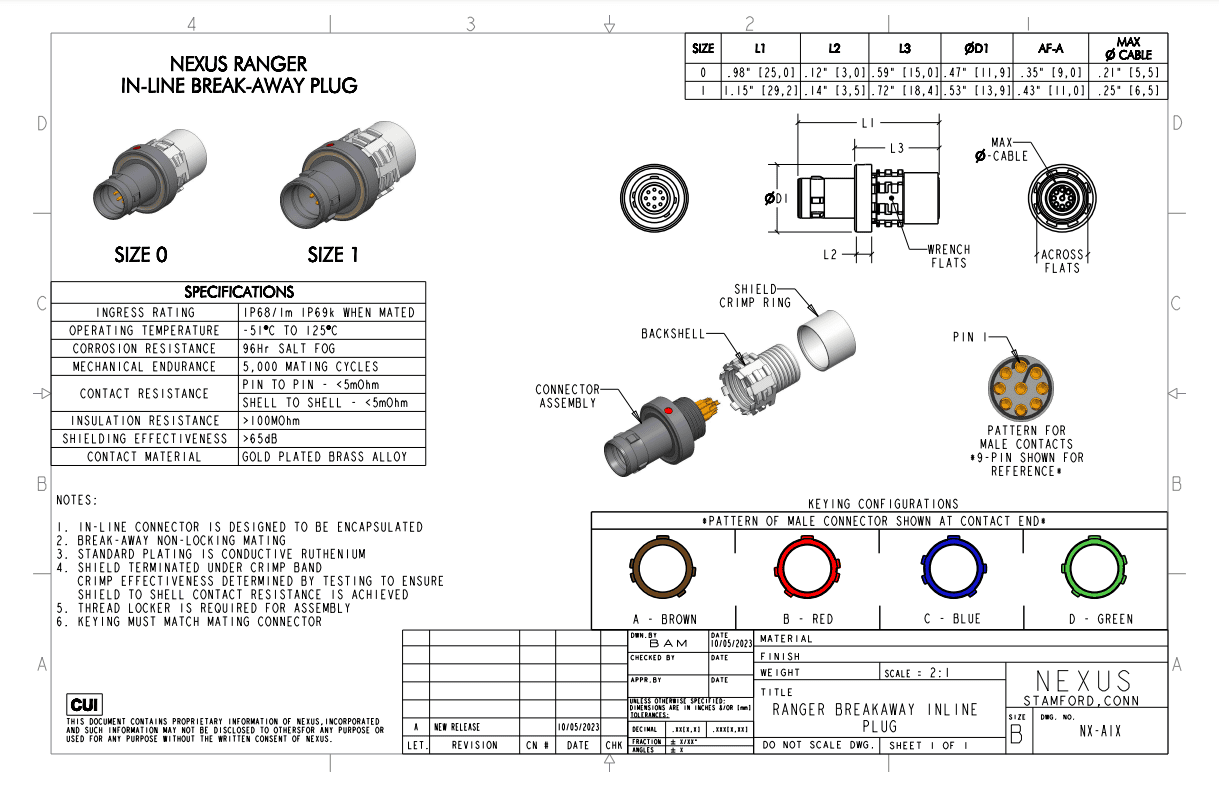

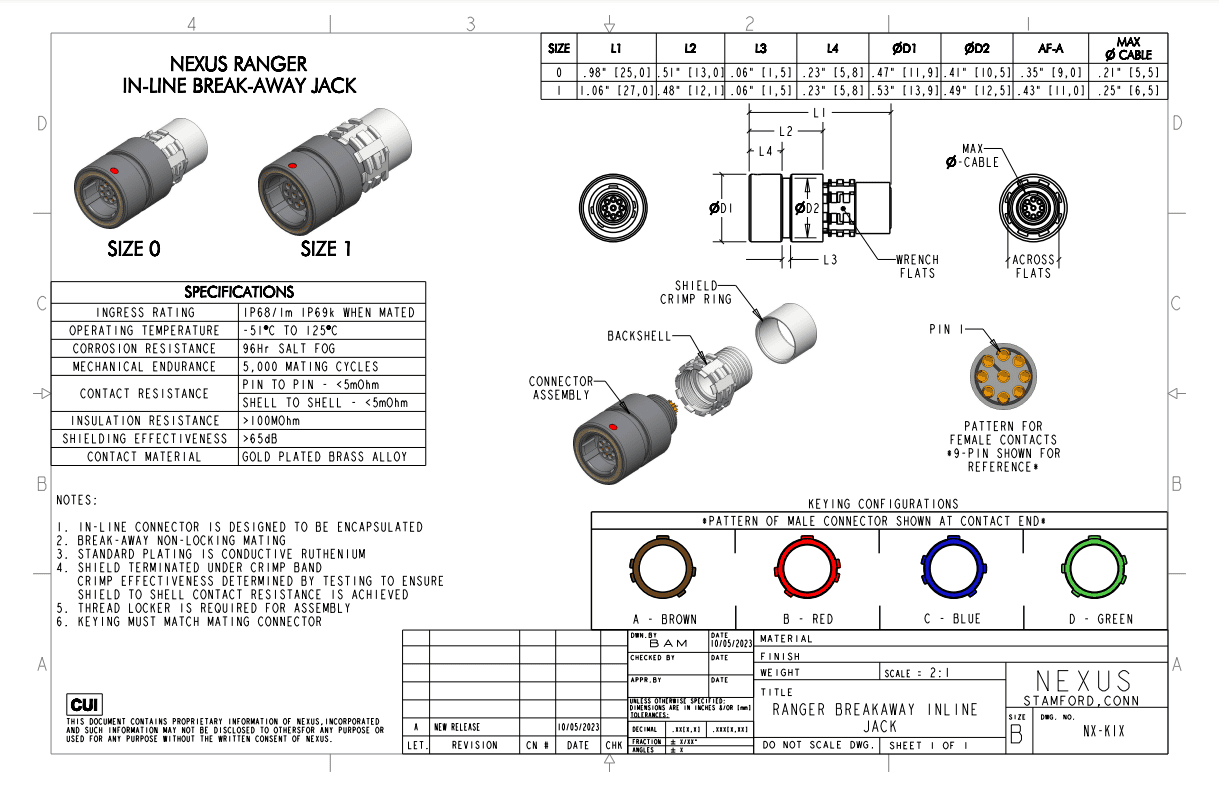

Connector Types and Custom Options

The Standard Ranger series is available in multiple connector styles to support a broad range of applications. These include in-line break-away plugs, in-line break-away receptacles, and panel mount receptacles. Designers can select from various contact layouts, ranging from 3 to 16 points, based on their signal and space requirements.

Shell sizes such as Size 0 and Size 1 are available, with four-keying options to help prevent mismating. Color-coded configurations to support organized installation, especially in systems with multiple connector sets.

For applications requiring more contact points in a smaller footprint, the Ranger line also includes High-Density configurations. These versions offer tighter contact spacing while maintaining compatibility with Standard Ranger housings. High Density options are ideal for compact systems where maximizing functionality within limited panel space is essential.

Application Areas

Standard Ranger connectors are built for use in demanding environments where reliability and quick-connect functionality are critical. Typical application areas include:

- Military communications – For radios, headsets, and intercoms used in field operations.

- Avionics systems – Suitable for cockpit and aircraft interfaces exposed to vibration and temperature shifts.

- Telecommunications – Applied in control systems requiring compact, consistent connections.

- Industrial equipment – Used in machinery, sensors, and control panels operating under shock and electrical noise.

- Mobile testing units – Ideal for equipment that requires frequent connections and disconnections.

- Modular assemblies – Supports rapid setup or reconfiguration in temporary or portable systems.

With strong resistance to vibration, shock, and environmental contaminants like dust and moisture, Standard Ranger connectors maintain signal integrity and mechanical stability in both fixed and mobile equipment.

Connect with Confidence with Amphenol NEXUS Technologies

Discover how the Standard Ranger can improve your system’s reliability and ease of use. Our team is ready to assist with technical questions or help you identify the right configuration for your needs. Whether you’re upgrading existing equipment or designing a new solution, expert guidance is available to support your project. Contact Amphenol NEXUS Technologies today to discuss your application and receive personalized recommendations. Let us help you streamline your connector selection and have a seamless integration.