Water from rain, humidity, or snow can easily damage electrical wiring, potentially causing shorts and starting fires. That’s why it’s important to use waterproof electrical connectors to protect the wiring from the elements. Waterproof electrical connectors are designed to keep water out of the connection point, preventing damage and ensuring a safe and reliable connection. Here we’ll discuss how waterproof electrical connectors work as well as their specifications and ratings for various environments.

How Waterproof Connectors Work

Waterproof electrical connectors are a critical component in applications where exposure to water is likely. They are commonly used in marine and outdoor settings, as well as in any indoor environment where high humidity is present. Waterproof electrical connectors form very tight seals to resist even the toughest high-moisture conditions.

This seal is possible through prongs that fit snugly around the connection points. The connectors are often coated with a waterproofing compound like rubber, which enters the receptacle end, fills in any gaps, and provides insulation against electrical shocks. As a result, waterproof electrical connectors provide a reliable and safe way to power equipment in potentially hazardous environments.

Ingress Protection (IP) Ratings

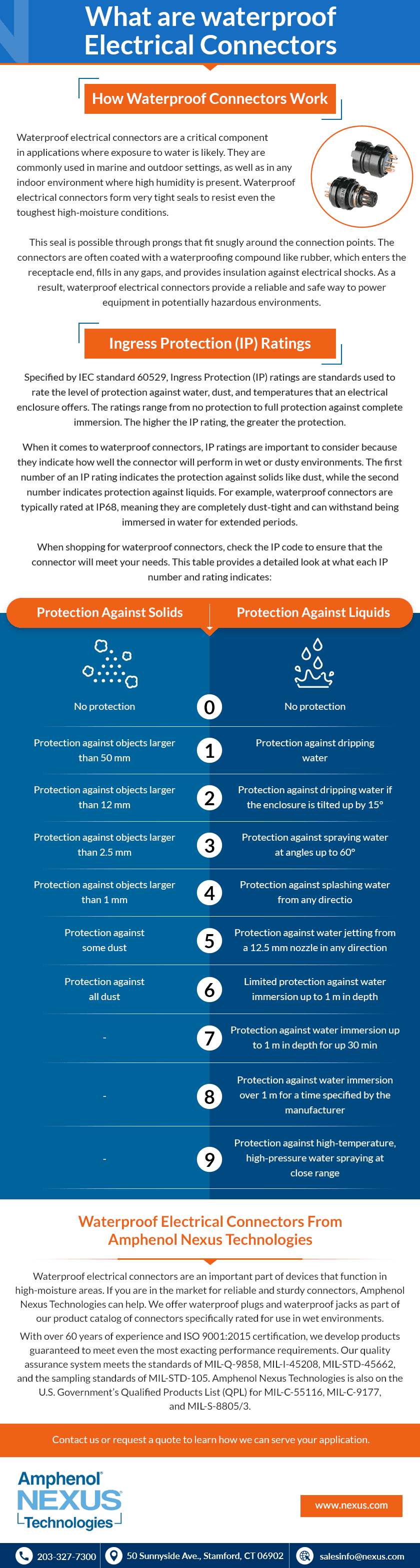

Specified by IEC standard 60529, Ingress Protection (IP) ratings are standards used to rate the level of protection against water, dust, and temperatures that an electrical enclosure offers. The ratings range from no protection to full protection against complete immersion. The higher the IP rating, the greater the protection.

When it comes to waterproof connectors, IP ratings are important to consider because they indicate how well the connector will perform in wet or dusty environments. The first number of an IP rating indicates the protection against solids like dust, while the second number indicates protection against liquids. For example, waterproof connectors are typically rated at IP68, meaning they are completely dust-tight and can withstand being immersed in water for extended periods.

When shopping for waterproof connectors, check the IP code to ensure that the connector will meet your needs. This table provides a detailed look at what each IP number and rating indicates:

| Protection against solids | Protection against liquids | ||

| 0 | No protection | 0 | No protection |

| 1 | Protection against objects larger than 50 mm | 1 | Protection against dripping water |

| 2 | Protection against objects larger than 12 mm | 2 | Protection against dripping water if the enclosure is tilted up by 15° |

| 3 | Protection against objects larger than 2.5 mm | 3 | Protection against spraying water at angles up to 60° |

| 4 | Protection against objects larger than 1 mm | 4 | Protection against splashing water from any direction |

| 5 | Protection against some dust | 5 | Protection against water jetting from a 12.5 mm nozzle in any direction |

| 6 | Protection against all dust | 6 | Limited protection against water immersion up to 1 m in depth |

| 7 | Protection against water immersion up to 1 m in depth for up 30 min | ||

| 8 | Protection against water immersion over 1 m for a time specified by the manufacturer | ||

| 9 | Protection against high-temperature, high-pressure water spraying at close range | ||

Waterproof Electrical Connectors From Amphenol Nexus Technologies

Waterproof electrical connectors are an important part of devices that function in high-moisture areas. If you are in the market for reliable and sturdy connectors, Amphenol Nexus Technologies can help. We offer waterproof plugs and waterproof jacks as part of our product catalog of connectors specifically rated for use in wet environments.

With over 60 years of experience and ISO 9001:2015 certification, we develop products guaranteed to meet even the most exacting performance requirements. Our quality assurance system meets the standards of MIL-Q-9858, MIL-I-45208, MIL-STD-45662, and the sampling standards of MIL-STD-105. Amphenol Nexus Technologies is also on the U.S. Government’s Qualified Products List (QPL) for MIL-C-55116, MIL-C-9177, and MIL-S-8805/3. Contact us or request a quote to learn how we can serve your application.